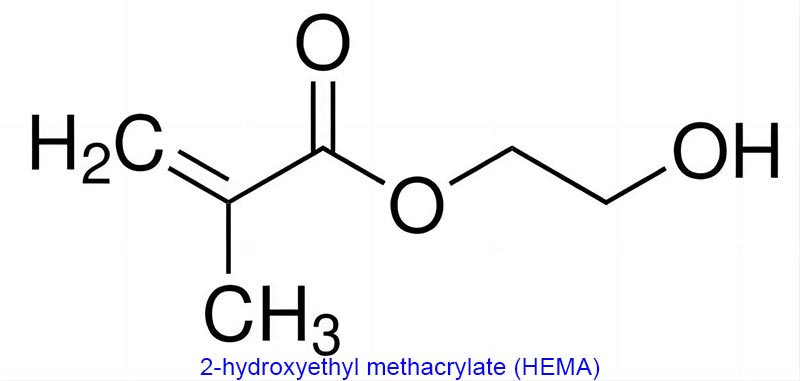

2-hydroxyethyl methacrylate (HEMA) is an organic polymerization monomer formed by the reaction of ethylene oxide (EO) and methacrylic acid (MMA), which contains bifunctional groups within the molecule. Hydroxyethyl methacrylate is a kind of colorless, transparent, and easily flowing liquid. Soluble in ordinary organic solvents. Miscible with water.

| ITEM | STANDARD LIMITS |

| CAS | 868-77-9 |

| Other name | HEMA |

| Appearance | Colorless and transparent liquid |

| Purity | ≥97.0% |

| Free acid(As AA) | ≤0.30% |

| Water | ≤0.30% |

| Chroma | ≤30 |

| Inhibitor(PPM) | 200±40 |

Application of HEMA

1. Mainly used for modifying resins and coatings. Copolymerization with other acrylic monomers can produce acrylic resins with active hydroxyl groups in the side chains, which can undergo esterification and crosslinking reactions, synthesize insoluble resins, improve adhesion, and can be used as fiber treatment agents. It reacts with melamine formaldehyde (or urea formaldehyde) resin, epoxy resin, etc. to manufacture two-component coatings. Adding it to high-end car paint can maintain its mirror gloss for a long time. It can also be used as an adhesive for synthetic textiles and medical polymer monomers.

2. HEMA is used to produce resins for coatings, automotive topcoats and primers, as well as photopolymer resins, printing boards, inks, gel (contact lenses) and tinning material coatings, transmission electron microscopy (TEM) and optical microscopy (LM) embedding reagents, especially for hydration samples of “sensitive antigen sites”. White water like, sticky, thinner than water, and easier to penetrate than any resin or monomer. Specially used for work on bones, cartilage, and difficult to penetrate plant tissues.

3. The plastic industry is used to manufacture acrylic resins containing active hydroxyl groups. The coating industry is used in conjunction with epoxy resins, diisocyanates, melamine formaldehyde resins, etc. to produce two-component coatings. The oil industry is used as an additive for lubricating oil washing. The electronic industry is used as a dehydrating agent for electron microscopes. Adhesives used in the textile industry to manufacture fabrics. Used as a chemical reagent in analytical chemistry. In addition, it is also used as a water-soluble embedding agent for synthesizing medical polymer materials, thermosetting coatings, and adhesives.

Future of HEMA:

Industry analysts have stated that due to its excellent comprehensive performance, hydroxyethyl methacrylate currently has a high demand for applications, especially in the fields of medical and high-end coatings, with promising prospects. There are still development opportunities in the future market of hydroxyethyl methacrylate. On the demand side: With the rapid growth of demand in fields such as coatings and adhesives, the consumption of 2-hydroxyethyl methacrylate is steadily increasing. Technically, HEMA production technology and polyether production technology can learn from each other in terms of design, equipment, process, and operation.In terms of industrial chain: the development of high-end hydroxyethyl methacrylate products can link up the upstream methacrylic acid and ethylene oxide devices, as well as the downstream water-based coating devices. At the same time, hydroxyethyl methacrylate is an important raw material for surface material business, ensuring the supply of key monomers for downstream business, expanding the industrial chain, and further increasing product value.With the increasingly strong market demand, the HEMA market is improving. In order to consolidate its market share, the company has decided to increase its original equipment production capacity and further purify the original process waste liquid to increase its own production capacity.

Post time: Jan-30-2024